Snowmobile Polaris EDGE / WIDETRAK (2007-2012 year). Instruction - part 18

3.10

Maintenance

9923396 - 2007-2012 EDGE/Widetrak LX Service Manual

©2011 Polaris Sales Inc.

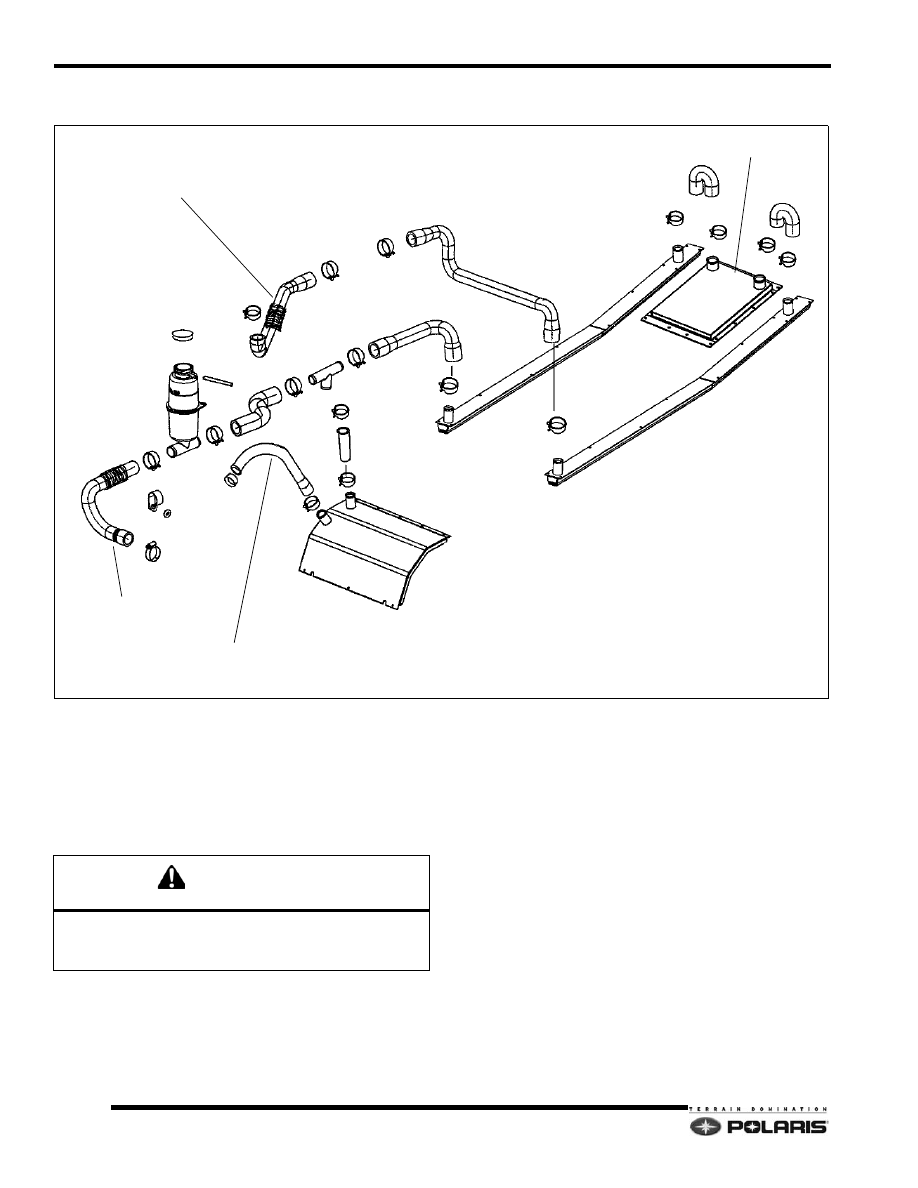

500 XCSP Cooling System

Surge Tank

Keep the level of the coolant inside the surge tank

between high and low marks. Coolant level will rise and fall

depending on the coolant temperature.

Always add coolant when the cooling system is COLD.

FRONT HEAT EXCHANGER

LEFT HEAT EXCHANGER

COOLANT HOSE

(FLOW = TO ENGINE)

BRAKE CALIPER

SURGE TANK

COOLANT HOSE

(FLOW = ENGINE OUT - THERMOSTAT OPEN)

RIGHT HEAT EXCHANGER

REAR HEAT EXCHANGER

COOLANT HOSE

(FLOW = ENGINE OUT - BYPASS CIRCUIT

CAUTION

Never remove the fill tube pressure cap when the cooling

system is warm. Severe burns to skin may occur from

escaping coolant or steam.