Snowmobile Polaris 550 IQ / 550 Shift (2012 year). Instruction - part 21

84

MAINTENANCE

Clutch System

Drive Belt Installation

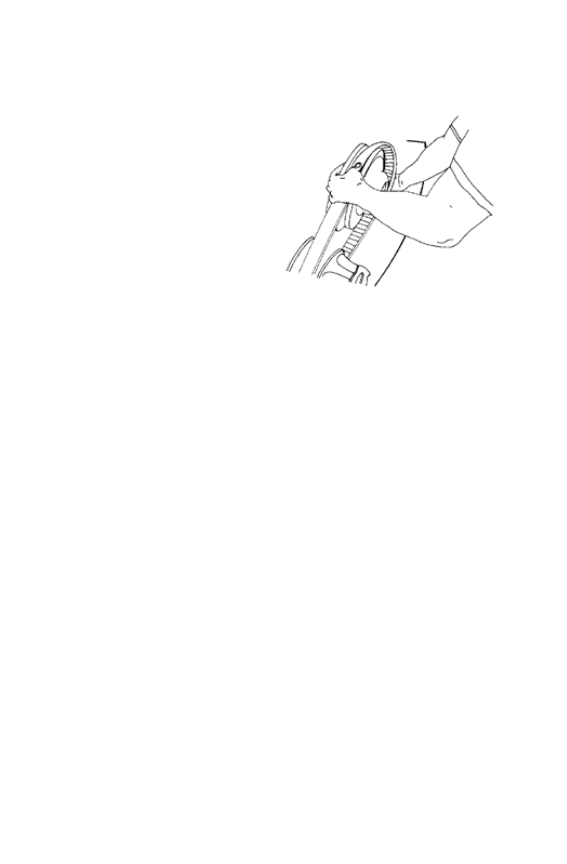

1. Drop the drive belt over the

drive clutch and pull back the

slack. The belt cord line

should be flush with, or

slightly above, the outer cir-

cumference of the driven

clutch sheaves. The belt will

seat itself in the driven clutch

during the break-in period.

Adjust the belt ride-out after

the break-in period by read-

justing belt deflection.

Tip: To ensure satisfactory belt life, install belts so they operate in the same

direction of rotation by positioning the identification numbers so that you

can read them. If required, separate the sheaves as outlined in the belt

removal procedures.

2. Rotate the L-wrench counter-clockwise to tighten the sheaves while

working the belt to the outer edge of the sheaves.

3. Remove the L-wrench and store it in the tool kit.

4. Reinstall the side panel.

5. Close and secure the hood.

6. Break in the new belt. See page 49.

Drive Belt

Belt width and length must match the center distance of the clutches and

sheave width of the drive clutch. POLARIS recommends the use of

O.E.M. belts. Other belts may match the dimensions, but can drastically

change the shift pattern, resulting in poor performance.

Tip: A worn belt will continue to function, but will not deliver maximum perfor-

mance. Always carry a spare belt in case of an emergency.