Operation & Maintenance Manual and User’s Service Guide for WP10 Series National IV Vehicle Diesel Engine (2010)

Operation & Maintenance Manual and User’s Service Guide

for WP10 Series National IV Vehicle Diesel Engine

Foreword

WP10 series National IV diesel engine is a high speed diesel engine developed with the adoption

of brand new design concept. This series diesel engine features compact structure, reliable uses,

excellent technical indexes (power performance, economy and emission), fast startup, simple

operations, and easy maintenance and is an ideal power unit for heavy-duty trucks and large-sized

luxury buses.

This manual provides an overview of the structural characteristics and operation and maintenance

precautions for WP10 series National IV diesel engine. While the user is using this diesel engine,

the truly fulfillment as per the requirements specified in this manual will surely prolong the

service life of diesel engine greatly.

The diesel engine covered by this manual is the basic model of WP10 series National IV diesel

engine. Following the continual development and improvement of the WP10 series product, we

hope that you can timely pay attention to all technical information released by our company. This

manual is subject to change without notice. Please access Weichai website at http://cn.weichai-

group.com for the latest product information.

You are welcome to put forward proposals and suggestions for further improvement to our

products.

August, 2010

Special Instructions

●

Before operation, the operator of the diesel engine must carefully read the Operation and

Maintenance Manual of the Diesel Engine and strictly abide by the operation and

maintenance practices specified in the operation and maintenance manual.

●

This diesel engine is tested strictly as per the test specification before delivery. Do not

adjust the ECU data at will to increase the power of diesel engine, otherwise our warranty

commitment will be voided.

●

The ECU, common rail fuel pump, and fuel injector are of precision parts. Do not

disassemble these parts by self, otherwise our warranty commitment will be voided.

●

The strict torque and angle requirements are specified for the main bearing bolts and

connecting rod bolts of the diesel engine. Please do not loosen or disassemble any bolt by

self. The connecting rod bolts are of one-time bolts and can’t be reused, otherwise our

warranty commitment will be voided.

●

The grades of the engine oil or fuel added into the diesel engine must conform to the

requirements specified in the operation and maintenance manual and the engine oil or fuel

added must be filtered by the special clean filter. The fuel shall be deposited for at least 72h.

Before driving the vehicle each time, make sure that the filling amounts of the coolant and

engine oil conform to the requirements.

●

It’s prohibited to run the diesel engine without air cleaner, in order to prevent the ingress of

non-filtered air into the cylinders.

●

While using a new engine, the user shall fulfill the 50h run-in.

●

After the cold start of the diesel engine, slowly increase the engine speed, instead of running

at high speed suddenly or long-term idling. After the running under heavy load, run the

engine at low speed for 5~10min before stopping, instead of stopping the engine suddenly

(except special cases).

●

After the engine is stopped, if the temperature of working environment is probably below 0º

and the coolant without antifreeze additive is used, fully drain the coolant from the water

tank and diesel engine.

●

The checking and repair for all parts of the electric system must be fulfilled by the

professional electric technicians.

●

The checking and repair for all parts of electronic control system must be fulfilled by the

professionals of our service station.

●

The diesel engine is oil sealed before delivery to prevent rusting. Generally, the oil sealing

period for diesel engine is one year. If the oil sealing time is more than one year, conduct

checking and take necessary supplemental measures.

Contents

I.

Operation and Maintenance Manual for WP10 Series National IV Vehicle

Diesel Engine

1

1.

Fuel, Lubricating Oil, Coolant, Urea Solution, and Auxiliary Materials for Diesel Engine

...........................................................................................................................................1

1.1

Fuel:

1

1.2

Lubricating Oil for Diesel Engine

1

1.3

Lubrication of Water Pump

1

1.4

Antifreeze Additive for Engine Cooling System

2

1.5

Urea Solution

2

1.6

Characteristics of Weichai Power Special Oil

3

1.7

Differences between Weichai Power Special Oils and Common Engine Oils

4

1.8

Some Common Products of Weichai Power Special Oils

4

1.9

Corresponding Table between Weichai Power Special Oils and Engine Models .. 5

1.10

How to correctly choose appropriate viscosity

5

1.11

Auxiliary Materials

5

2.

Uses and Operations of Diesel Engine

7

3

Periodical Checking and Technical Maintenance of Diesel Engine

12

4

Analysis and Troubleshooting of Common Malfunctions

24

II.

User Service Guide (Warranty Card)

38

Warranty Card for Weichai Power Products (To be preserved by user)

38

Maintenance Registration Form (To be filled by maintenance personnel)

39

Warranty Instruction

40

Rule of Warranty Period for Weichai Power Diesel Engine

42

Weichai International Marketing Service Network

错误!未定义书签。

Engine Mandatory Maintenance Card

44

Customer Satisfaction Survey

47

I. Operation and Maintenance Manual for WP10 Series

National IV Vehicle Diesel Engine

1.

Fuel, Lubricating Oil, Coolant, Urea Solution, and Auxiliary Materials for

Diesel Engine

1.1

Fuel:

Summer: 0# diesel (GB252)

Winter: Generally, appropriate grade of diesel fuel shall be selected depending on the actual

environment temperature

Attention: The fuel in use must conform to the requirements in Appendix C of national standard

GB 17691-2005 (Revised in June, 2008).

1.2

Lubricating Oil for Diesel Engine

The capacity of lubricating oil depends on the marking of the oil dipstick (The oil capacities vary

depending on different models).

Choice of lubricating oil: To ensure safe and reliable running of your diesel engine, please choose

grade 15W/40 CF-4 or 20W/40 CF-4 lubricating oil. The 15W/40CF-4 oil can be used under the

temperature range of -15℃~+30℃, the 20W/40CF-4 oil can be used under the temperature range

of -10℃~+30℃ (The Weichai Power special oil is recommended), the 5W/20CF-4 shall be

adopted for the temperature below -15ºC.

Table 1 Table for Choice of Lubricating Oil Grades

Environment

Environment

Multiple grades of oil

temperature

temperature

Attention: It’s disallowed to use grade CE, CD, CC, CB, or CA lubricating oil for WP10

series National IV diesel engine. The engine oil filter element shall be replaced at each

replacement of engine oil.

1.3 Lubrication of Water Pump

The water pump shall be lubricated by general lithium-based lubricating grease for vehicles (Refer

to standard GB/T5671-1995).

1

1.4

Antifreeze Additive for Engine Cooling System

The glycol antifreeze additive is adopted. It’s allowed to substitute with home-made long-acting

antifreeze additive, provided that the quality of such additive is reliable. Please refer to the

relevant instructions for the specific operation methods. Two home-made long-acting antifreeze

additives that are available recently are recommended as below:

JFL-336# long-acting antifreeze additive

FD-30# long-acting antifreeze additive

It shall be noted that the long-active antifreeze additive in use shall be periodically replaced as per

the relevant requirements.

1.5

Urea Solution

The inappropriate urea solution will easily lead to poisoning failure of SCR catalyst or insufficient

reduction rate (For instance, the out-of-tolerance of phosphor, sodium, potassium, and calcium

contents in the urea solution will easily lead to poisoning of catalyst and the out-of-tolerance of

urea solution concentration will easily lead to excessive leakage of NH3 or insufficient reduction

rate of NOx) and out-of-tolerance of emission and warning of malfunction indicator lamp.

Therefore, the quality and the performance of urea solution in use shall meet the requirements

specified in standard ISO 22241.

Table 2 Contents of Urea (Refer to standard ISO 22241)

Content

Unit

Minimum

Maximum

Urea mass percentage

%

31.8

33.2

Density at 20℃

kg/m3

1087

1093

Refraction rate at 20℃

-

1.3814

1.3843

Ammonia soda mass percentage

%

-

0.2

Biuret mass percentage

%

-

0.3

Acetaldehyde

mg/kg

-

5

Insoluble substance

mg/kg

-

20

Phosphorus (Phosphorus tetroxide)

mg/kg

-

0.5

Calcium

mg/kg

-

0.5

Ferrum

mg/kg

-

0.5

Copper

mg/kg

-

0.2

Zinc

mg/kg

-

0.2

Chromium

mg/kg

-

0.2

Nickel

mg/kg

-

0.2

Aluminum

mg/kg

-

0.5

Magnesium

mg/kg

-

0.5

Sodium

mg/kg

-

0.5

Potassium

mg/kg

-

0.5

2

1.6

Characteristics of Weichai Power Special Oil

1.6.1

High configuration guarantees high quality

The imported fine hydrocracking base oil and imported composite additive are mainly selected to

guarantee the high quality of lubricating oil.

1.6.2

Under normal working conditions, the oil replacement interval can be prolonged by

3,500~7,000km (The oil replacement interval can be prolonged to 10,000km for CH-4). The

excellent high temperature oxidation resistance and outstanding retentivity of base number (TBN)

effectively prolong the oil replacement interval of engine.

1.6.3

Professional protection prolongs engine life

Through a great number of performance and durability tests in response to the Weichai engine, the

professional compound for lubricating oil of high horsepower and high load engine is developed

to provide professional protection for Weichai engine and effectively prolong the service life of

engine (by 30%~40% against common engine oil).

1.6.4

Better performance requirements

It features better wear resistance, base number retentivity, rusting protection, oxidation resistance,

fuel consumption control, and shear stability and reduces the formation of deposits in the

turbocharger.

1.6.5

Energy-saving

With

“low viscosity

+ multi-polarization

+ friction improving agent”, the energy-saving

compound features high viscosity index of oil, good oil film strength and elasticity, and stable

running, low resistance and low fuel consumption of the engine.

1.6.6

Low contents of ash, sulfur and phosphorous and better environment-friendly

The maximum ash content of 1.0% prolongs the service life of diesel particle filter (DPF). The

maximum sulfur content of 0.4% prevents the failure of oxidation catalyst (DOC) and reduces the

particulate matters. The maximum phosphorous content of 0.12% prevents the failure of DOC and

the failure of NOx control system. The volatility can be controlled at 13%.

3

1.7

Differences between Weichai Power Special Oils and Common Engine Oils

Item

Special engine oil

Common engine oils

Mainly the imported class Ⅲ hydrocracking base oil is

Mostly the home-made class I or

Base oil

adopted

a little class II base oil is adopted.

Mainly the imported quality composite additives are

Additives

Home-made additives

adopted

The targeted professional compound features good

lubrication performance, strong cleanliness, and

effectively improved fuel economy (saving fuel by

Only the general lubrication

Performance

3~8%) and provides professional caring for the engine

performance can be met.

under harsh working conditions (heavy load or heavy

dust).

Oil replacement

During normal use, the oil replacement period can be

Conventional value

period

prolonged by 3,500~7,000km (by 10,000km for CH-4)

1.8

Some Common Products of Weichai Power Special Oils

Type

Grade

Specification

Package capacity

15W/40

WP-E1 (CD)

20W/50

4L,18L,200L

10W/30

15W/40

WP-E2 (CF-4)

20W/50

4L,18L,200L

Diesel engine oil

10W/30

5W/30

15W/40

WP-E3 (CH-4)

4L,18L,200L

20W/50

10W/30

WP-E4 (CI-4)

15W/40

4L,18L

85W/90

Heavy-load vehicle gear oil

GL-5

4L,18L

80W/90

4

1.9

Corresponding Table between Weichai Power Special Oils and Engine Models

Standard number

Type

Recommended main applicable models

of special oil

WP-E1

Medium speed diesel engine unit

(CD)

WP-E2

National I and National II diesel engines; construction machinery (50

High speed engine

and 30 loaders); WD618/WD12 series and WD615/WD10 series;

and high

(CF-4)

226B and medium speed engine; heavy-duty trucks of 15t and above.

horsepower

medium speed

WP-E3

National III diesel engine; Landking Engine series; ultra-heavy duty

diesel engine

truck; bus; WP4/WP6

(165~270HP), WP10 (240~375HP), WP12

(CH-4)

(336~460HP), WD10, WD12, and WP5/WP7 (160~300HP).

WP-E4

National IV series (including ultra-heavy duty truck)

(CI-4)

Compressed natural gas engine and bus and alternator unit fitted with

Gas engine

CNG

compressed natural gas engine

1.10

How to correctly choose appropriate viscosity

Applicable environment

SAE viscosity grade

temperature (ºC)

5W/30

-30~35

Lubricating oil

10W/30

-25~35

15W/40

-20~40

20W/50

-15~50

85W/90

-15~49

Gear oil

80W/90

-25~49

85W/140 (higher viscosity than 85W/90)

-15~49

1.11

Auxiliary Materials

No.

Name

Color

Applications

Applied on smooth metal surfaces to prevent seizure

Molykotte Pulver

1

Black

For instance: Applied onto outer surfaces of cylinder

(Fine molybdenum powder)

liner

Molykotte G.u.plus

Achieve lubrication function before establishment of

lubricating oil pressure

2

Dark grey

(Molybdenum disulfide oiling

agent)

For instance: Applied onto intake valve stem.

5

Table 3 Reference Table for Application of Sealant for Diesel Engine

Additional

Trademark

Main Applications

List of locations for application of sealant

description

Flywheel housing bolt

Camshaft thrust plate bolt

Camshaft timing gear bolt

Intermediate idler bolt

Front end cap bolts

It’s applied onto the

Engine oil filter seat bolt

threads to prevent being

Loctite 242

vibrated to looseness,

Alternatively, the

Engine oil cooler bolt

with moderate strength.

DriLoc204 thread

Screw plug of engine oil cooler regulator valve

pre-application

sealant can be pre-

Bolt of oil pump return pipe fixing device

applied.

Air compressor shaft end thread

Strainer bolt

Bolt of sensor and harness fixing device

It’s applied onto the

external threads to lock,

Loctite 262

Cylinder head auxiliary bolt

seal, and prevent being

vibrated to looseness

Loctite 271

Locking and tightening

Bowl plug for oil port

For sealing between

Loctite 277

Other bowl plugs

element and bore

For sealing top surface of

Loctite 270

Push rod tube - Cylinder head

cylinder head

Mating face between cylinder block and

crankcase

Between front end face of engine block and

front end cap and between rear end face and

flywheel housing connecting plate

Mating face between engine oil filter seat and

Loctite 518

crankcase

It’s applied onto shining

(Updated

metal surfaces for sealing

Water pump rear cap - Engine block front end

product of

purpose.

face

510)

Flywheel housing connecting plate - Flywheel

housing

Mating face between cylinder block and engine

oil cooler

Mating face between cylinder block and engine

oil filler port cover

6

2.

Uses and Operations of Diesel Engine

2.1

Unsealing of Diesel Engine

After the diesel engine is unpacked, the user shall firstly count the diesel engine and its accessories

as per the delivery packing list, check the exterior of diesel engine for presence of damage and the

connectors for presence of looseness, and then conduct the following works:

◆ Wipe the anti-rusting layer and anticorrosive agent on the exposed parts.

◆ Drain the oil sealing oil from the inside of fuel filter and the parts of fuel system (It’s

allowed to start the engine without draining the oil sealing oil from the fuel system.

However, it’s permitted to run the engine under loaded condition only when the oil sealing

oil in the fuel system is used up and the diesel fuel is supplied to the engine normally).

Attention: Generally, the oil sealing period for diesel engine is one year. If the oil sealing

time is more than one year, conduct checking and take necessary supplemental measures.

◆ Rotate the flywheel and spray solvent into the intake pipe, till the oil sealing oil in the

cylinder is completely removed.

◆ Spray solvent to the intake and exhaust ports of the turbocharger, till the oil sealing oil is

completely removed.

◆ As agreed between the manufacturer and the user, the oil sump not filled with oil shall be

added with oil as specified. For the oil sump filled with engine oil containing run-in

accelerator at the time of delivery, it’s recommended to drain oil and replace with new oil

after the initial 2,000km mileage (or 50 running hours).

◆ If the coolant is filled fully before delivery as agreed between manufacturer and user to meet

the user’s demands, check the performance of coolant at the time of unsealing. If the

antifreeze capability meets -30ºC or -35ºC, with PH value at 7~8 (neutral) and total hardness

at 5~15ºD [9~15ºf (hardness)], the coolant can be used. If disqualified, drain the coolant and

refill the coolant with antifreeze additive.

7

2.2

Hoisting of Diesel Engine

During the hoisting, maintain level the centerline of engine crankshaft. It’s prohibited to hoist in

tilted or at one side. Hoist up and down slowly (Refer to Figure 2-1).

Correct

Wrong

Figure 2-1

Hoisting Diagram of Diesel Engine

2.3 Installation of Diesel engine

For supply installation, ensure that the crankshaft centerline of the diesel engine is coaxial with the

axis of input shaft of drive unit

(gearbox, transmission, or alternator) and ensure that the

crankshaft is free of additional axial force due to installation.

2.4 Preparations before Start

◆ Checking of Coolant Level

If the engine is installed on the vehicle or on the stand, the coolant level is visible from the glass

sight hole on the expansion water tank at all times. If the coolant is insufficient, add coolant

through the filler port cap. While opening the filler port cap with pressure relief valve and air

bleeding button, if the engine is under hot state, make sure to push down the air bleeding button to

open the cap. It’s prohibited to add a great amount of coolant while the engine is under hot state,

as the high thermal change will damage the parts. If there is not coolant under special cases, it’s

allowed to slowly add cool water with not very low temperature. Add the coolant through the filter

port, till the coolant overflows. Start the engine. While the engine is running

(1,000r/min),

continue to add the coolant, till the coolant level is stable, and finally install the filler port cap.

8

◆ Checking of fuel level

If the engine is installed on the vehicle, turn on the power switch and check the fuel level from the

fuel gauge or check the fuel tank.

◆ Checking of engine oil level

The engine oil level shall be between upper and lower markings of the oil dipstick. If necessary,

add engine oil through the engine oil filler port.

◆ Checking of urea level in urea tank

Generally, the urea consumption accounts for 3~5% of the fuel consumption (by volume). Check

the level of urea solvent depending on the working condition. Maintain the level at 30~80% and

timely add if insufficient. Do not add excessive urea, or it will lead to overflow of urea.

Figure 2-2

Urea Level Marking in Urea Tank

◆ Checking of diesel engine accessories

Check various accessories of diesel engine for reliable connections and resolve any abnormal

phenomenon. Check the starter system for normal wiring and check whether the battery is

sufficiently charged. Then, open the fuel tank valve, loosen the air bleeding bolt on the fuel

strainer, and use manual pump on the fuel strainer to bleed the air from the fuel system. Check the

SCR system for reliable pipeline connections. No leakage of urea solvent is allowed.

9

2.5

Start of Diesel Engine

◆

Place the power switch and electric key on the vehicle to position START, place the gearshift

lever to neutral gear, and begin to start the engine.

◆

Turn the electric key to start the diesel engine. If the engine fails to start in 5~10s, wait for

1min before retry. If the engine can’t be started by three consecutive attempts, stop the

attempt and find out and resolve the malfunction before retry. After the start of engine,

observe the readings of various instruments. The engine oil pressure gauge shall indicate the

pressure immediately. Pay attention not to run the cold engine at high speed. Firstly, idle run

the engine for a while. However, do not idle run the engine for a long period.

◆

The auxiliary starter shall be used to start the diesel engine under cold temperature. By means

of the electric heating flange via relay, the engine can start successfully under

-30ºC

environment.

2.6

Running of Diesel Engine

◆

After the diesel engine is started, idle run for several minutes and then increase the speed to

1,000~1,200r/min and apply partial load. It’s permitted to run the engine under full load only

when the water outlet temperature is higher than 60ºC and the engine oil temperature is

higher than

50ºC. The load and speed shall be increased gradually. Avoid the haste

acceleration and haste application of load as far as possible.

◆

Within the 60h run-in period (or the initial 3,000km mileage) of the diesel engine, it’s

preferable to run the engine under moderate load and without trailer.

◆

Timely decelerate the engine while driving on slopes. It’s not preferable to run the engine for

a long period under high torque condition. In addition, it’s not preferable to run the engine

under extremely low load or speed, or it will easily lead to malfunctions such as oily smoke.

◆

During normal use of the diesel engine, it’s permitted to continually run the engine at rated

power and rated speed. However, if running the engine at 105% of rated speed and 110% of

rated power, it’s permitted to run the engine for up to 20min. Once unloaded, please idle run

the diesel engine for 1~2min before stopping the engine.

◆

Parameters and checking locations to be real-time observed in using:

Pressure of main lubricating oil passage: 350~500kPa;

Oil temperature of in oil sump: <110℃.

Coolant outlet temperature: 80+5º, no more than 105ºC.

Exhaust temperature after turbine: <600℃;

10

Intake temperature after inter-cooler: 50~55ºC.

Check the color of exhaust gas to judge the working quality and application load of the fuel

injector. If the color of exhaust gas is really bad, stop the engine for checking.

Pay attention to observe the diesel engine for presence of water, air and fuel leakages. If any, stop

the engine for troubleshooting.

◆

The operator shall understand the following characteristics of diesel engine:

① The fuel consumption is really low when the torque output is at maximum value and

increases along with the increasing of speed.

② The torque reaches the best value at the moderate speed range of the engine

(1,200~1,600r/min).

③ The power output of the engine increases along with the increasing of the speed and

reaches rated power at the rated speed.

◆

Precautions for running under cold environments:

① Fuel: Choose diesel fuel of different grades depending on the outdoors temperature in

winter.

② Lubricating oil: Choose lubricating oil of different viscosities depending on the seasons.

③ Coolant: Add antifreeze additive into the cooling system and choose antifreeze of

different trademarks and quantities depending on different outdoors temperatures.

④ Start: The auxiliary starter can be adopted if necessary in winter. After the start of the

diesel engine, wait for the oil pressure and water temperature are normal before running

at high speed under loaded condition.

⑤ Before the approach of the cold season, make sure to check the electrolyte level and

viscosity and unit voltage of the battery. If the diesel engine is not to be used for a long

time and is under extremely low temperature, remove the battery and store in a warmer

indoors place.

⑥ Stop: To stop the engine under cold weathers, unload the engine, idle run the engine for

1~2min, and wait for the water temperature and oil temperature to cool down before

stop. Please be noted that it’s disallowed to drain the coolant containing antifreeze

additive. If the coolant contains no antifreeze additive, make sure to open the water

drainage valves or water plugs on the engine block, engine oil cooler cap, radiator, and

water inlet pipe to fully drain the coolant, in order to prevent the frozen cracking of the

engine.

11

3 Periodical Checking and Technical Maintenance of Diesel Engine

3.1

Daily Maintenance

Check the coolant level, engine oil level, and fuel level, check the lubricating grease application

points for sufficient lubricating grease, check for leakage of oil, water and gas, check the

peripheral parts and accessories for good connections and fastening, check the fan and belts for

presence of over-tightness and looseness, check the oil pressure and coolant temperature of the

diesel engine, check the temperature, color of exhaust gas, the sound and vibration of the engine

for normality, and check the engine for stable speed.

◆ Check the coolant level and temperature

Observe the coolant level via glass sight hole. If the coolant is insufficient, open the filler port cap

and add coolant.

Attention: While opening the filler port cap, make sure to push down the air bleeding button,

in order to prevent the coolant from causing personal injuries under hot state of engine.

Figure 3-1

Expansion

water tank

Figure 3-2

12

◆ Check engine oil level

It’s prohibited to start the diesel engine when the oil level is below lower marking of oil dipstick

or is above upper marking of oil dipstick.

After the diesel engine is stopped, wait for at least 5min before checking the oil level, in order to

enable the engine oil to have sufficient time to flow back to oil sump.

The oil amount difference between lower marking and upper marking of oil dipstick is 3L.

Figure 3-3

◆ Check fuel level

Check for leakages: The entire engine shall be free of leakage of water, gas or oil.

13

Figure 3-4

◆ Check the urea solvent level

The urea solvent level shall be maintained at 30~80% of total capacity of urea tank.

◆ Check the fan

Visually check the blades of fan for presence of damage and check connecting bolts for fastening.

Figure 3-5

◆ Check belt

14

The belt is automatically tensioned by belt tensioner. Check the tension of belt by pushing the belt

with hand.

Figure -3-6

◆ Check exhaust gas for normal color

The normal color of exhaust gas is light grey. In event of change in color, check cause and resolve,

as shown in Figure 3-6.

◆ Check for normal sound

◆ Check for normal speed and normal vibration

5.2

Items for various levels of maintenance

In addition to the daily maintenance items, fulfill the following items:

◆ Replace the diesel engine oil.

◆ Screw off the oil drainage plug from the bottom of oil sump to fully drain the engine oil and

then screw on the oil drainage plug, as shown in Figure 3-7.

◆ Open the oil filler cap (as shown in Figure 3-8), add engine oil through engine oil filler port,

observe the level of oil dipstick till the required oil level is reached, and then install the oil

filler cap.

15

Oil drainage plug

Figure 3-7

Engine oil filler port

Figure 3-8

Attention: The waste oil shall be placed in designated location and container to ease the

recycling.

16

◆ Replace engine oil filter or filter element. See Figure 3-9:

At the replacement of engine oil filter, operate as per the following procedure:

① Remove used engine oil filter.

② Fill the new filter completely with clean engine oil.

③ Before installing new engine oil filter, apply engine oil onto the rubber gasket.

④ After the rubber gasket comes into contact with the base, tighten for 3/4~1 turn to seal.

⑤ Start the diesel engine and check for presence of oil leakage.

Engine oil filter

Figure 3-9

◆ Replace the fuel filter element. See Figure 3-10.

At the replacement of fuel filter, operate as per the following procedure:

① Remove the used fuel filter element. The water collector installed on the strainer can be

reused. Please take out the water collector.

② Lubricate the sealing port.

③ Screw on the filter with hand, till the sealing port comes into contact with the connecting

port.

④ Continue to screw on the filter with hand, till the filter is securely installed (for

approximate 3/4 turn).

⑤ Bleed the air, till there is no presence of air bubble.

17

⑥ Conduct the leakage test.

Fuel filter

Figure 3-10

Attention: At the replacement of strainer or at the reinstallation of fuel delivery pipe, it’s

necessary to bleed the air from the strainer.

Procedure: (As shown in Figure 3-11).

① Stop the engine.

② Remove the air bleeding screw.

③ Pump up fuel filter with the manual pump, till only the fuel overflows from the air

bleeding screw.

④ Retighten the air bleeding screw.

18

Figure 3-11 Air bleeding of strainer

Drain the water from the water collector:

Attention: When the water collector is full or the spin-on filter is replaced, it’s necessary to drain

the water collected.

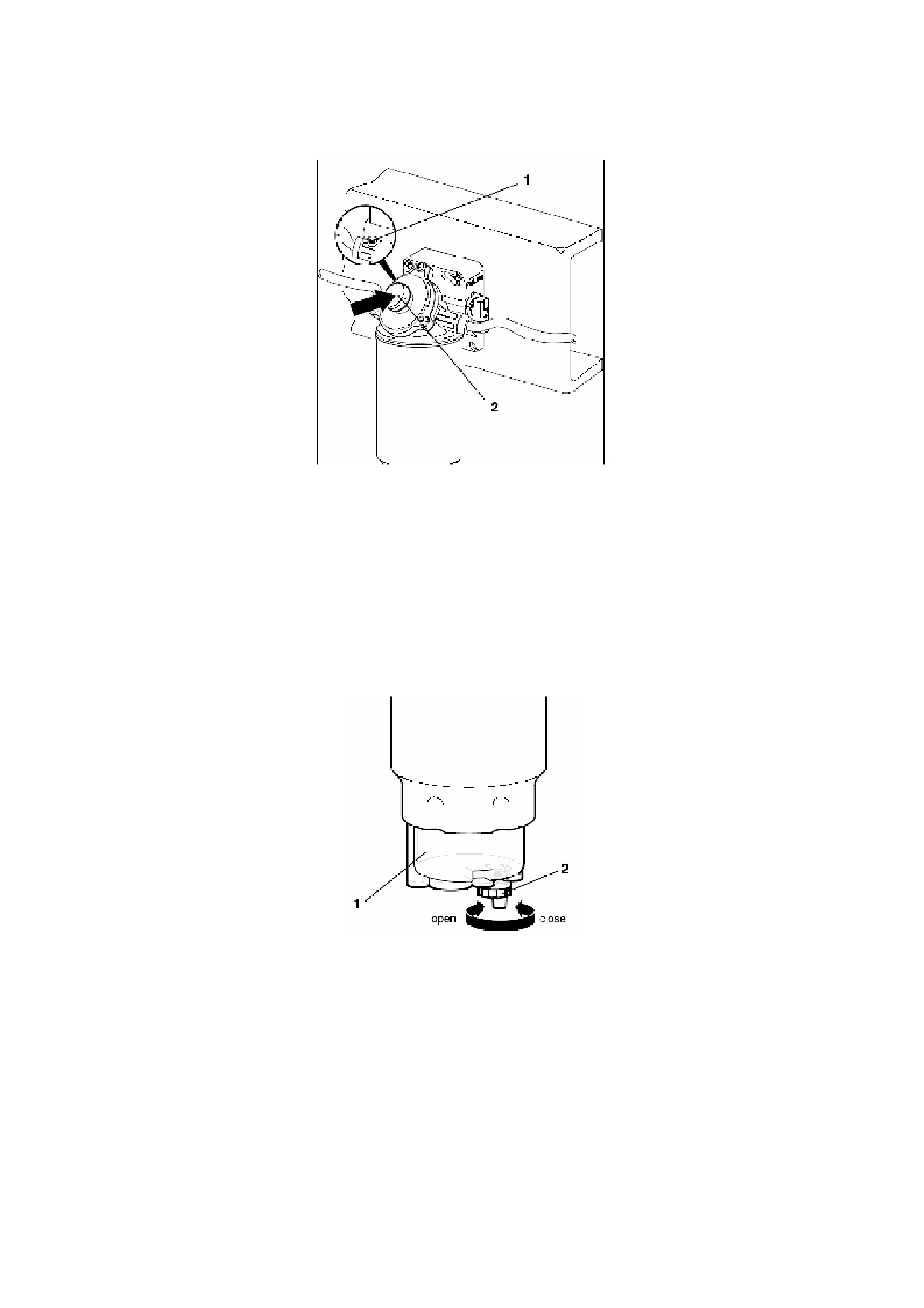

Procedure (As shown in Figure 3-12)

②

Open the fuel drainage plug 2 on the bottom of water collector 1 to fully

drain the water.

② Retighten the fuel drainage plug.

Figure 3-12

19

Replace the water collector:

Procedure (As shown in Figure 3-13)

① Stop the engine.

② Drain water from the water collector.

③ If possible, remove the screw 1 of water collector with hand. If the screw 1 is too tight,

use the remover tool attached in the new water collector.

④ Lubricate the seal ring 2 of new water collector with several drops of oil.

⑤ Install the screw with hand and tighten with tool.

⑥ If the water collector is reused on a new spin-on filter, check for presence of damage.

⑦ Install with torque wrench and tighten to 20N.m.

Figure 3-13 Replacement of water collector

◆ Check the air intake system

Check the intake hose for presence of aging or cracking and check the hoop for presence of

looseness. When necessary, tighten or replace parts to ensure air-tightness of intake system.

20

◆ Check urea pump filter element

At the time of maintenance, it’s necessary to remove the filter element of urea pump and

thoroughly clean with clean water before installation. Do not slap or knock the filter element with

high force.

◆ Check the urea nozzle gasket

At each replacement or disassembly/installation of urea nozzle, it’s necessary to check the status

of urea nozzle gasket. In event of damage or deformation, replace the urea nozzle gasket.

◆ Clean the urea tank and urea tank filter element

At the time of maintenance, it’s necessary to check the cleanliness of urea tank and filter element

and when necessary clean.

3.3

Maintenance for long-term storage of diesel engine

◆ Clean the diesel engine.

◆ Take protective measures:

① After the engine warm-up, drain the engine oil, clean engine oil filter, and add anti-

rusting oil.

② Drain the fuel and refill anti-rusting oil mixture.

③ Drain the water and add coolant with anti-rusting agent.

④ Start the engine and idle run for 15~25min.

⑤ Fully drain the engine oil, fuel, coolant and urea solvent.

⑥ Take protective measures for other portions.

◆ Protection during storage:

Plug with caps or wrap with plastic film all inlets and outlets of oil, gas and water and seal up the

entire diesel engine with weather anti-rusting film.

◆ If the transport is required, the outer package shall be supplemented.

21

3.4 Fulfill the maintenances and complete maintenance records

Table 3-1 Operation Conditions for Two Classes of Vehicles

(Class WG I)

(Class WG II)

Harsh working conditions (cold or hot weathers, heavy dust, short-

All kinds of commercial vehicles with

distance transport, operation in working sites, and bus, municipal

more than 2×104km yearly driving

engineering vehicle, snow sweeper, and fire truck) or no more than

mileage

2×104km yearly driving mileage or no more than 600h working hours

Table 3-2 Maintenance Period

Working condition

Driving mileage (time)

WG I

WG II

Item

Initial mandatory

3000km (50h)

A

A

maintenance

10000km (200h)

B

C

30000km (400h)

B

Routine maintenance

For class WG II vehicles, replace the engine oil filter element at the Weichai’s

designated service center at interval of 10,000km (200h)

A - Initial mandatory maintenance: Replace oil and oil filter element and do not replace fuel strainer and fuel fine

filter elements.

B - Routine maintenance: Replace engine oil, engine oil filter element, fuel strainer and fuel fine filter elements.

C - Only replace oil filter element.

22

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

Table 3-3

Maintenance Specification of Diesel Engine

1st

Maintenance item of

Routine

Level 1

Level 2

Level 3

Level 4

checki

diesel engine

checking

maintenance

maintenance

maintenance

maintenance

ng

Replacement of oil (at

●

●

●

●

●

●

least once a year)

Replacement of oil filter

●

At each replacement of diesel engine oil

element

Checking and adjustment

●

●

●

●

●

of valve clearance.

Replacement of fuel filter

●

●

●

●

element.

Cleaning of fuel strainer

or replacement of filter

●

●

●

●

element

Checking of coolant

●

●

●

●

●

●

amount and refilling

Replacement of coolant

Replace once a year

Fastening of cooling

●

pipeline clamps

Fastening of intake

pipeline, hose and flange

●

●

●

●

●

connector

Checking of air cleaner

maintenance indicating

●

●

●

●

lamp or indicator

Cleaning of air cleaner

dust collector (except

●

●

●

●

●

automatic dust discharge

type)

Cleaning of air cleaner

When the indicator lamp lights up

main filter element

Replacement of air

cleaner main filter

Refer to relevant regulations of vehicle manual

element

Replacement of air

cleaner safety filter

After main filter element is cleaned for 5 times

element

Checking and fastening

●

●

●

●

●

●

of belt

Checking of turbocharger

●

bearing clearance

Urea pump filter element

●

●

●

●

Urea nozzle gasket

At each disassembly of urea nozzle

Cleaning of urea tank and

●

●

●

●

urea tank filter element

Note: ● denotes necessity of maintenance.

The relevant maintenance must be conducted for the diesel engine that is stored for more than half

year, such as oil resealing.

Weichai will provide maintenance recommendations upon request of the user.

23

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

4 Analysis and Troubleshooting of Common Malfunctions

WP10 series National IV diesel engine is designed and manufactured under strict quality

assurance system and each delivered diesel engine passed the specified tests. In addition, the

diesel engine is a kind of precision machinery and the long-term guarantee of its functionality is

closely related to the normal maintenance. The causes leading to earlier failure of diesel engine are

generally as below:

◆ Operations against rules or improper management and operations.

◆ Failure to fulfill maintenance as specified or even repair works instead.

◆ Poorly manufactured parts, especially the counterfeit products procured due to

temptation of cheap prices, which will greatly shorten the service life of diesel engine.

Inappropriate grade of fuel or lubricating oil or disqualified fuel or lubricating oil

4.1 Diagnosis method

The common diagnosis methods for malfunctions of diesel engine are generally as below:

◆ Observation method: Judge the malfunction situation by observing the malfunction symptom,

such as exhaust smoke of diesel engine.

◆ Listening diagnosis method: Judge the characteristic and extent of the malfunction portion by

listening as per the abnormal sound of diesel engine.

Figure 4-1

24

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

Figure 4-2

◆ Cylinder interruption method: Interrupt the working of certain cylinder to judge whether the

malfunction occurs in such cylinder. Generally, the cylinder interruption method is to cut off

the fuel supply to the suspiciously malfunctioned cylinder and compare the status changes of

the engine before and after the interruption of cylinder, in order to narrow the scope for

further detection of the malfunction portion or cause.

◆ Comparison method: For some assemblies or parts, the replacement method is adopted to

determine the presence of malfunction.

Attention:

① Judging the malfunction formation cause of diesel engine is a really careful work.

Before the cause is basically identified, do not disassemble the diesel engine casually, or

it will not only eliminate the malfunction, but also lead to more serious malfunction due

to improper assembly after disassembly.

② For critical parts such as high pressure fuel pump, ECU, rail supply pipe, and

turbocharger, please have them checked and repaired by Weichai’s designated service

station.

25

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

4.2 Common Malfunctions and Troubleshooting

4.2.1 Start failure of diesel engine

(1) No working of starter

The starter of WP10 series National IV diesel engine is controlled by ECU. During normal

working, the ECU outputs a current to drive the starter relay and, after the relay is actuated, the

battery drives the start of the starter. In event of malfunction, mainly check the neutral gear.

There are several elements during the checking: Relevance of neutral gear switch, starter relay,

battery and underframe stop switch.

◆ Check whether it is shifted at neutral gear

Before the start, firstly check whether the gearshift lever is shifted at neutral gear.

◆ Check the position of underframe stop switch (which shall be under OFF state)

The underframe stop switch is of inching type and is capable of automatic reset. Check this switch

for normal functioning.

If this switch is other than automatic reset type, check whether this switch is at ON state.

◆ Check the neutral gear switch and wiring for intactness. Try to use the emergency start (Push

down and hold the ignition switch for more than 5s).

For the engine with starter controlled by ECU, at the time of start, the ECU will firstly judge

whether it’s at neutral gear as per the signal transmitted from neutral gear switch. If the neutral

gear switch is damaged or the wiring is poorly connected, the ECU fails to receive neutral gear

signal and the starter can’t work.

◆ Check whether the battery voltage is too low to drive the starter

Generally the battery voltage is 24V. The under-low voltage can’t drive the working of starter.

Use the voltage measurement of multimeter to check or read the actual “battery voltage” by

malfunction diagnostic unit.

◆ Check starter relay and wiring for intactness

Check surfaces of wiring terminals for presence of excessive oxide and check the bolts on surfaces

of wiring posts for looseness and breakage.

◆ Check the starter for burnout

Use a multimeter to check the starter relay for normal working.

◆ Check whether the ignition switch and starter switch are damaged.

26

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

Turn the ignition key to position ON and observe whether the instrument lamps light up.

Turn the ignition key to position START and observe whether the starter acts (Provided that all

other causes are excluded)

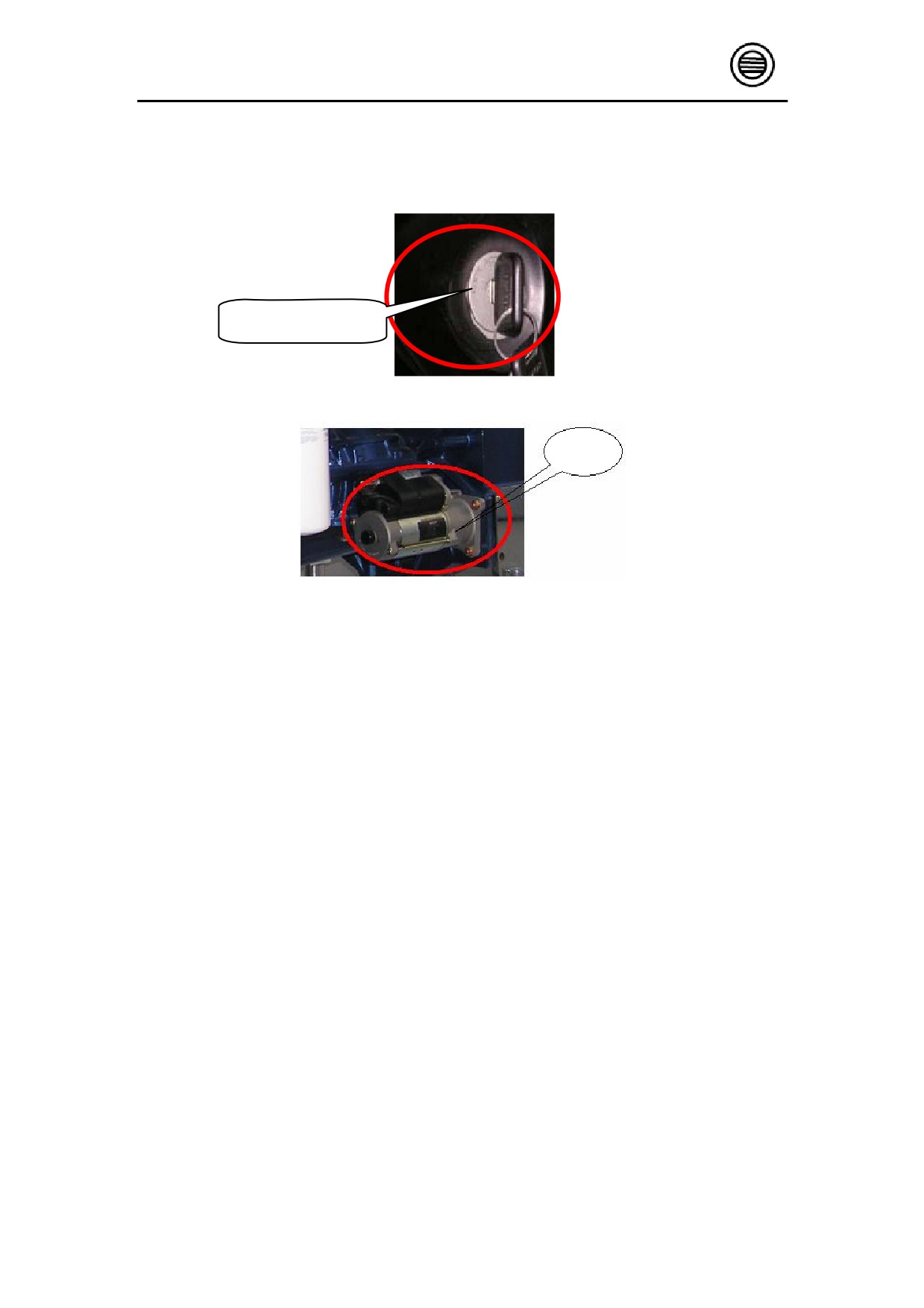

Ignition key switch

Figure 4-3

Starter

motor

Figure 4-4

27

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

(2) Establishment failure of rail pressure (The starter can work normally, but can’t start)

Air bleeding

bolt

Figure 4-5

◆ Check the fuel tank for low fuel level. This cause can be easily ignored and shall be paid with

attention.

◆ Check the manual fuel pump for normal working and push the manual fuel pump with hand

to check for normality.

◆ Check the low pressure fuel line for presence of air and bleed the air (Sometime the leakage

of low pressure fuel line is not obvious and shall be carefully checked)

Air bleeding method: Mainly bleed the air from the strainer. Loosen the air bleeding bolt on the

strainer and push the manual pump on the strainer with hand, till the fuel flows out continually at

the air bleeding bolt.

If the diesel engine can’t be started after the air in the low pressure fuel line is completely bled, it

can be judged that there is air in the high pressure fuel line and it’s necessary to bleed the air from

high pressure fuel line.

Air bleeding method: Loosen high pressure fuel pipe for certain cylinder and drive the working of

diesel engine with starter, till the fuel flows out continually from the high pressure fuel pipe (It’s

recommended not to disassemble the high pressure fuel pipe connector frequently!)

◆ Check the high pressure fuel line for presence of leakage

This symptom is relatively obvious. Check the nut of high pressure fuel pipe connector for

presence of looseness. If yes, tighten the nut.

◆ Check the fuel line for blockage and check the diesel filter for presence of blockage. It’s

recommended to timely replace the diesel filter element.

28

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

Checking method: Loosen the outlet bolt of filter, drive the running of diesel engine with starter,

and observe for spray-out or flow-out of diesel. If only a small amount of diesel flows out, it can

be determined that the filter element is blocked. In such case, it’s necessary to replace the filter

element.

◆ Check whether the initial voltage of the rail pressure sensor is at approximate 500mV or the

rail pressure setting is at 30~50MPa.

(3) Improper connection of engine harness or vehicle harness or open-circuit or short-

circuit of harness

◆ Check the installations of connectors and use a multimeter (preferable “circuit diagnostic

unit”) to check the continuity of circuit as per the pin definition of the circuit diagram.

(4) Loss of crankshaft signal and camshaft signal

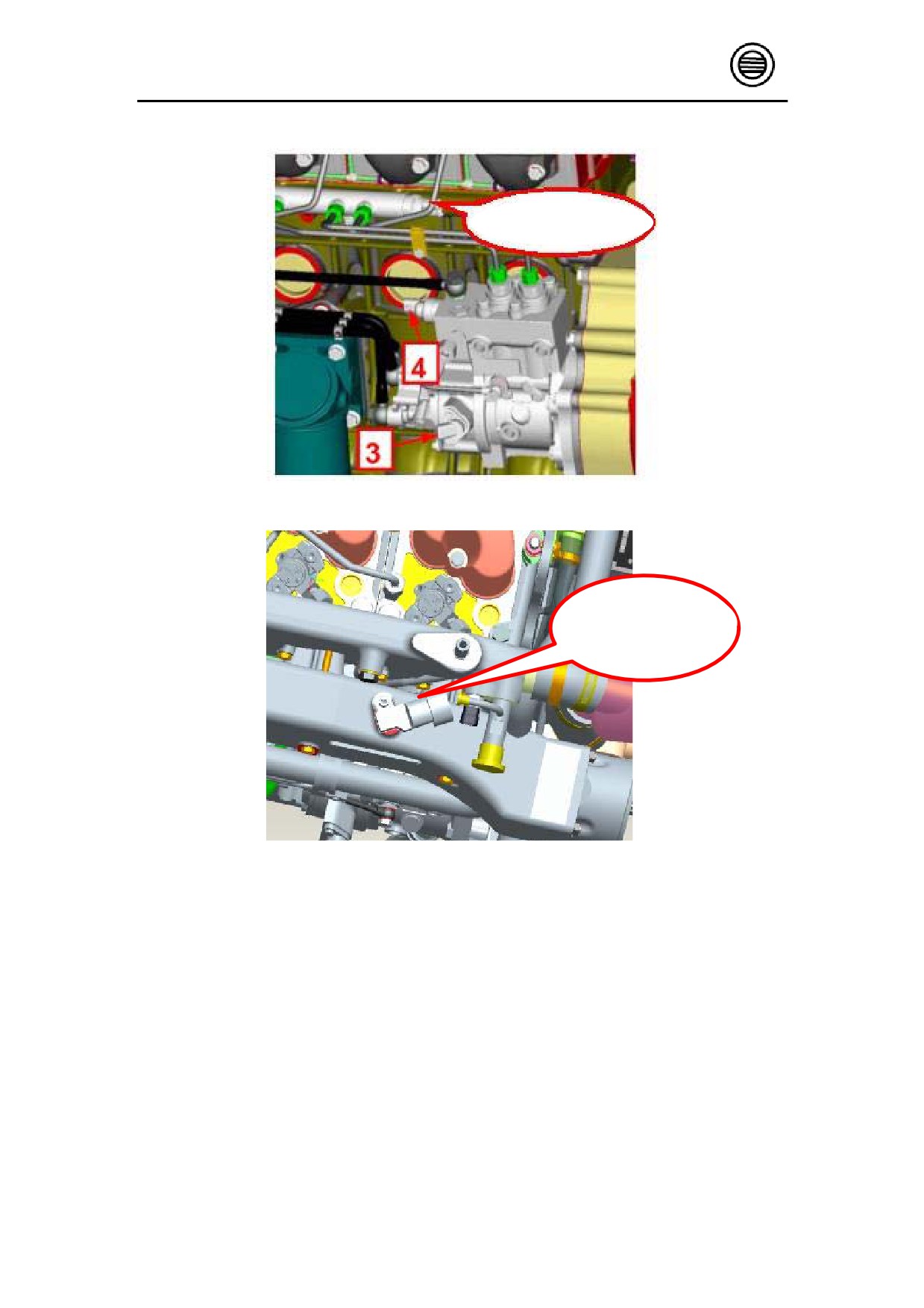

Two speed sensors are installed on the diesel engine, on the outer sides of flywheel housing and

high pressure fuel pump respectively. The functions are crankshaft position sensor and cylinder

judgment sensor respectively. The fuel injection timing of the electronically controlled engine

depends on these two sensors. In event of start failure of diesel engine, both the signals are lost

completely.

◆ Possible cause for loss of both signals

(1) Damage of sensor or short-circuit or open-circuit of harness

(2) Insecure fixing of sensor, leading to over-high or under-low gap between sensor and inductive

tooth (generally 1±0.5mm)

Troubleshooting: Check the sensor for presence of damage, check the harness for good connection,

and check the sensor for looseness.

◆ After the disassembly of high pressure fuel pump and flywheel, the reinstallation shall be

conducted strictly as per the relevant process documentation, in order to ensure signal

synchronization.

29

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

Camshaft speed sensor

Figure 4-6

Crankshaft speed sensor

Figure 4-7

30

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

4.2.2

Difficult start

Cause and troubleshooting for difficult start of engine:

◆ The diesel engine is not running for a long time: The fuel return pipe shall reach beneath the

fuel level.

◆ There is a small amount of air in low pressure pipeline: Bleed the air.

◆ The crankshaft speed signal and the camshaft signal are weak and the synchronization

judgment time is long: Find out specific cause and readjust.

◆ The environment temperature is too low or the preheater is failed: Check the heating flange

for normal wiring or replace preheater.

◆ Poor or disqualified fuel or oil: Replace with quality fuel or oil.

◆ Broken teeth of starter or flywheel gear ring: Replace starter and flywheel gear ring.

◆ Wear of piston ring and cylinder liner or poor sealing of valve: Replace piston ring, cylinder

liner or valve seat and valve

◆ Blockage of exhaust brake butterfly valve at OFF state, leading to choked exhaust: Replace

the butterfly valve.

4.2.3

Low engine power

Limping home: One running mode of engine under malfunctioned state. Upon detection of engine

malfunction, the ECU will not stop the engine immediately. Instead, it will restrain the engine

power in such manner that the engine speed can only accelerate to 1,500r/min so that the driver

can drive the vehicle to the nearest service station for repair.

(1) Malfunction of fuel injector

The malfunction of fuel injector is generally composed of mechanical malfunction and wiring

malfunction.

The mechanical malfunction is the blockage of needle valve. Due to excessive dirt in the diesel

fuel or corrosion from air ingress, the needle valve is blocked within the fuel injector against

actions (Attention: The ECU may not report error!).

Wiring malfunction is the disconnection of harness or short-circuit of harness to ground due to

direct grounding of the cylinder head, arising from the causes such as vibration and wear. In such

case, the ECU will report error.

31

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

Fuel injector wiring

Figure 4-8

(2) Over-high water temperature, oil temperature or intake temperature

When the water temperature, oil temperature or intake temperature is over-high, the ECU will

activate the overheating protection function to restrain the engine power.

Before solving the malfunction, firstly the distorted feedback of sensors and instruments shall be

excluded.

◆ Causes and troubleshooting for over-high water temperature

① Low level in water tank: Check for leakage and add water

② Slow speed or no rotation of fan: Check the drive parts of fan

③ Blockage of water tank: Check water tank and clean or repair

④ Loose water pump belt: Adjust the tension as specified

⑤ Damage of water pump gasket or wear of water pump impeller: Check and repair or

replace

⑥ Thermostat malfunction: Replace

32

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

⑦ Damage of water pipe seals or ingress of air: Check water pipes, connectors and gaskets

and replace damaged parts

◆ Causes and troubleshooting for over-high engine oil temperature

① Low level or oil shortage in oil sump: Check oil level and leakage, repair and add oil

② High water temperature: Check and resolve the above-mentioned causes leading to over-

high water temperature

③ Blocked flow of oil cooler: Check and clean

◆ Causes and troubleshooting for over-high intake temperature

Check the heat radiation capability of inter-cooler.

(3) Signal synchronization error

In event of this problem, generally the signal of one sensor is failed.

Read the flash code by flash code lamp and find out and resolve the specific cause with reference

to the flash code table.

(4) Malfunction of flow metering unit

The flow metering unit is the actuator for control of rail pressure and is installed on the high

pressure fuel pump. When it's malfunctioned, the high pressure fuel pump will supply fuel to the

common rail pipe at its maximum capacity. In such case, the pressure relief valve on the common

rail pipe generally opens and there is a “click” noise in the diesel engine. There is a similar

symptom when the rail pressure sensor is malfunctioned.

Flow metering unit

Figure 4-9

◆ Troubleshooting: Check the circuit, determine the malfunction of flow metering unit or rail

pressure sensor, and notify the office for handling.

33

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

(5) Abnormal fluctuation of rail pressure due to leakage of fuel pipeline

During the traveling of the vehicle, the vehicle speed will be unstable and the vehicle will have

symptom of forward jumping.

◆ Troubleshooting:

Restart after 1min power cutoff. If the problem still exists, check the air-tightness of fuel pipeline

and resolve.

(6) Sensor malfunction

The intake pressure sensor is the sensor used by ECU to estimate the air intake flow (installed on

the intake pipe). The water temperature sensor is the sensor used to judge the thermal load of the

engine (installed on the water outlet pipe). The rail pressure sensor is used to check the fuel

pressure of common rail tube (installed on the common rail tube).

Water temperature sensor

Figure 4-10

34

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

Rail pressure sensor

Figure 4-11

Intake pressure &

temperature sensor

Figure 4-12

35

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

◆ Troubleshooting

Check the intake temperature and pressure sensors, water temperature sensor and rail pressure

sensor and check the connectors for secure connection.

Attention: In event of malfunction 1, 3, 4, 5 or 6, the diesel engine will enter the “Limping

Home” mode.

4.2.4

Constant running of engine at 1,000r/min

In such case, the throttle is failed. The ECU judges the load as per the signal from the pedal

potentiometer. In event of malfunction of pedal, for safety consideration, the ECU will control the

diesel engine to automatically drop to 1,000r/min idling.

◆ Loose electronic throttle pedal wire or error connection

Reconnect or check throttle for correct wiring and reconnect the wiring.

◆ Water ingress in connector of electronic throttle pedal

Use a tool to blow the connector and then start the engine.

Attention: At the replacement of throttle pedal, keep the same model of pedal.

4.2.5

Swing during idling of engine

◆ Causes and troubleshooting for rough idling of engine:

① Abnormal working of fuel injector: Check fuel injectors and harnesses for all cylinders.

② For the complete vehicle with vehicle speed sensor, there is an input of vehicle speed signal

when the vehicle is parked: Check the speedometer and signal and wiring of vehicle speed

sensor.

36

Operation & Maintenance Manual for WP10 Series National IV Vehicle Diesel Engine

WEICHAI

③ Poor fuel quality, with water or waxy content: Clean fuel system and replace fuel filter

④ Air ingress in low pressure fuel pipeline: Check air-tightness of fuel pipes and

connectors and bleed the air

⑤ Unstable atomization of fuel injector nozzle: Check and repair.

Attention: It’s a normal function of ECU that the idling speed is increased due to low water

temperature. If other load is available (for instance, the air conditioner is turned on), the

idling speed will be increased naturally!

4.2.6

Malfunction of SCR

◆ Failure for normal injection of urea

If the SCR system is not working during normal running of the engine, check the connectors at

SCR urea pump, urea nozzle and urea sensor for reliable connections and check the urea

connection pipelines and connectors for presence of bending, looseness or breakage.

Check the urea level in urea tank. If the urea is insufficient, add the urea timely. In event of poor

quality of urea solvent, with excessive impurities, check the cleanliness in the urea tank and clean

the urea tank depending on actual condition. Check the contamination state of the urea pump filter

element and clean the filter element of urea pump depending on actual condition. In event of

serious contamination, replace the filter element. Check the contamination in the vicinity of the

urea nozzle port. If the urea nozzle port is blocked, clean or replace the urea nozzle.

When the engine is running under cold weathers, it’s normal if the urea solvent can’t be normally

sprayed as the unfreezing of urea is not completed. If the unfreezing can’t be completed after a

long period, the heating function is probably malfunctioned and it’s necessary to contact the

service station.

◆ Increased exhaust backpressure of engine

In event of serious black smoke or increased fuel consumption during running of the engine, check

the inside of exhaust pipe for serious crystallization or stone of urea. The low environment

temperature and poor atomization of urea sprayed by the urea nozzle will probably lead to clear

crystallization of urea on the inner walls of pipeline. Depending on the actual condition, take the

heat preservation measures for the walls of exhaust pipe or check the blockage of urea nozzle.

Check catalyst carrier within the SCR tank for presence of falloff or breakage and timely contact

the service station.

37

WEICHAI

II. User Service Guide (Warranty Card)

Warranty Card for Weichai Power Products (To be preserved by user)

Name

Description

Name

Description

Model

User Name

Ordering number

Postal code

Number

Address

Purchase date

Office tel.

Dealer

Residence tel.

Distinguished user:

Welcome to using Weichai product and thanks for your favor to Weichai product!

To use and maintain the diesel engine correctly, please carefully read the operation and

maintenance manual of diesel engine and operate strictly as per the relevant regulations. In event

of malfunction of diesel engine, please contact Weichai Service Center or Customer Service

Center of Weichai Power. We will provide you with timely and effective repair services.

Some items of the “Maintenance Registration Form” are to be filled by the Service Center. Please

properly preserve the “Maintenance Registration Form”.

Weichai Power Co., Ltd.

Address: No. 26, Minsheng East Street, Kuiwen District, Weifang, Shandong, China

Postal Code: 261001

Website: http://www.weichai.com

Sales hotline for engines: 0536-8232488

8233371

Sales hotline for parts: 0536-2297313

2297319

Service hotline:

400 toll-free service hotline: 400-6183066

24-hour service hotline

800 toll-free service hotline: 800-8603066

Customer Service Center Hotline: 0536-8235369 (fax)

Customer Service Center Complaint Hotline: 0536-2297322

38

WEICHAI

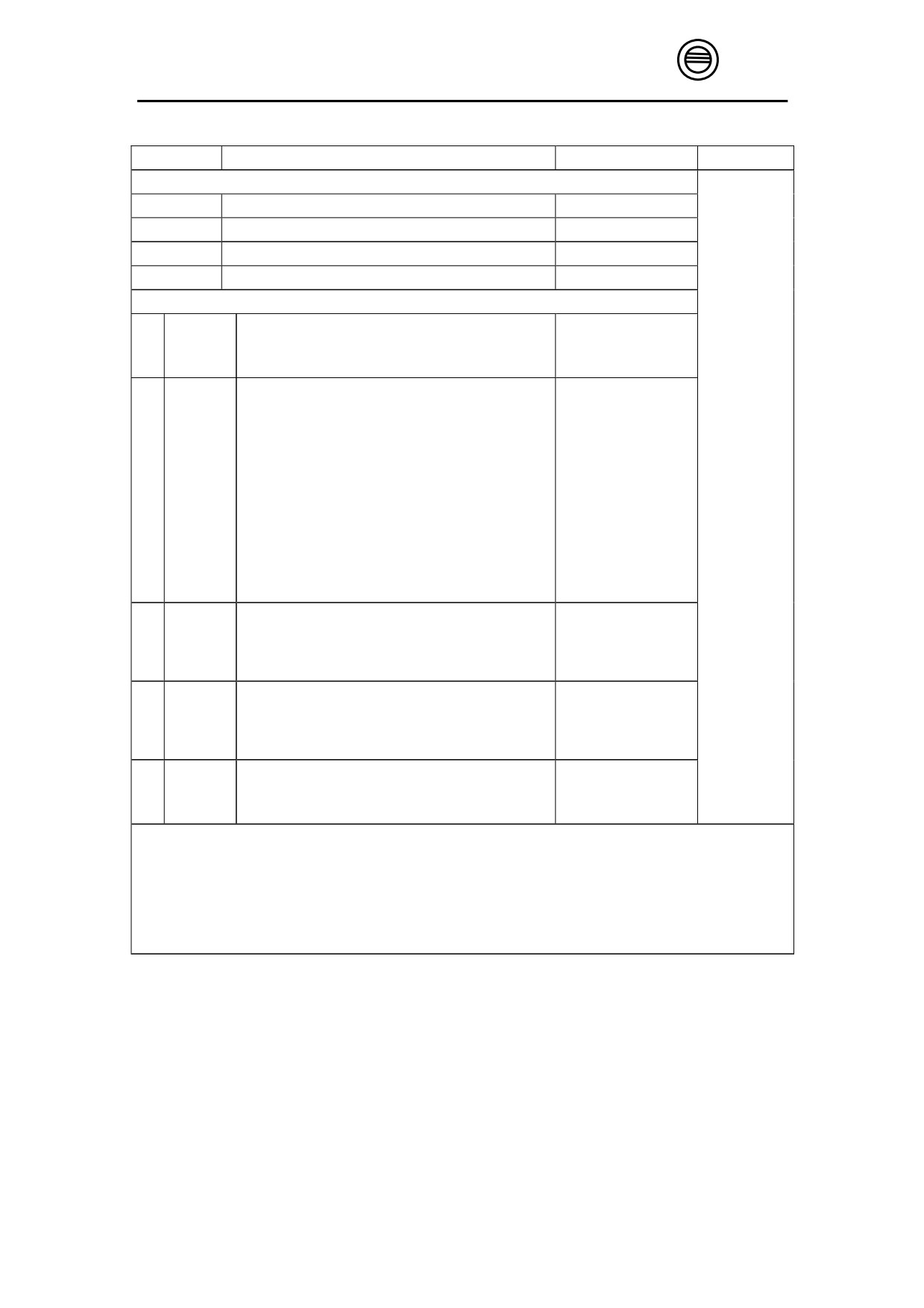

Maintenance Registration Form (To be filled by maintenance personnel)

Name

Description

Name

Description

Model

User Name

Ordering number

Postal code

No.

Address

Purchase date

Office tel.

Dealer

Residence tel.

Seal of

Name of service

Maintenance

Replacement

Date

Quantity

maintenance

Seal of user

center

items

parts

personnel

39

WEICHAI

Warranty Instruction

1. Service Commitment

Within the responsible service region, upon receipt of the user’s information, the service unit of

our company will arrive at the service site within 3 hours for the city in which the service unit is

located, within 24h for general areas, and 48h for remote areas once the service need is confirmed

(except the force majeure factors).

2. Special Instructions

● The operator of the diesel engine must carefully read the operation and maintenance manual,

understand the structure of diesel engine, strictly abide by the technical operation and

maintenance practices specified in the manual, and pay attention to the warning instructions

and warning signs.

● This diesel engine passed our company’s tests strictly as per the test specification before

delivery and it's absolutely prohibited to change the ECU data without consent, otherwise

Weichai will not provide warranty services.

● There are strict torque requirements and service times for various bolts of the diesel engine.

Do not loosen the main bearing bolts or connecting rod bolts at will. Refer to the operation

and maintenance manual for the specific requirements.

● Please fulfill the 50h run-in while using a new engine.

● After the cold start of the diesel engine, slowly increase the engine speed. Do not run at high

speed suddenly or idle run for a long time.

● It’s prohibited to run the diesel engine without the air cleaner, in order to prevent the ingress

of non-filtered air into the cylinders. Under harsh working environment, increase the cleaning

or replacement times of the air cleaner filter element, in order to prevent malfunctions (such

as earlier wear) of diesel engine.

● While adding fuel and engine oil into the diesel engine, make sure to select the specified

trademarks. Make sure to use Weichai special oil and special clean container. The oil shall be

filtered by filter screen during refilling.

3. “Warranty” Service Principle and Rule

(1) Warranty service principle

● After the user purchases Weichai product or vehicle equipped with Weichai product, under

normal operation and maintenance conditions, Weichai product is warranty covered within

warranty period against all damages due to assembly or manufacture causes of the product.

● For the diesel engine and its parts, the repair is the priority method. Those determined as non-

repairable shall be replaced. For the replacement of entire engine, the conditions of Weichai

Power Co., Ltd. for replacement of entire engine must be met and the request shall be

submitted to the responsible leader for approval.

(2) Warranty Period

40

WEICHAI

●

For the end-products manufactured by Weichai, the warranty service and warranty period

shall start from the actual purchase date and shall be based on the sales invoice and warranty

card of Weichai or the sales invoice of the dealer (For the marine main unit, the warranty

period shall start from the actual adjustment test date of the engine).

●

The warranty for the products supplied to the vehicle manufacturers shall be as agreed by

both parties. If the vehicle manufacturer has explicit rules on the warranty of engine, the rule

of the vehicle manufacturer shall be followed, with the criterion as per the vehicle attached

warranty card. If there is no explicit criterion or contents on the warranty service of the engine,

the criterion of Weichai shall be followed. The warranty service and warranty period shall

start from the actual purchase date of the vehicle and shall be based on the sales invoice and

warranty card.

●

If the parts purchased from Weichai are attributed to the original quality cause, the warranty

period is 3 months for assemblies and 1 year for basic parts. No warranty is provided for the

wearing parts, rubber parts, piston rings, oil seals, bushings, bolts and fuel injector couplings

once they are assembled on the engine. In event of quality issues of basic parts within

warranty period, upon the site confirmation of the service personnel from externally station

center with the presence of effective photos, the labor cost will be calculated for the warranty

service. The warranty period for the spare parts is based on the date of sales invoice of the

central warehouse or the authorized service center. For the assembly quality issues, Weichai

will not provide warranty service and the warranty service shall be provided by the assembly

unit.

4.

Rule for exclusion of warranty

●

The malfunctions of diesel engine due to improper use, maintenance or matching. Such as the

damage due to loading and unloading during self transportation, the application conditions out

of the scope specified in the operation manual of the product, improper matching, over-speed

and over-load use, the failure for fulfillment of run-in or maintenance as specified in

operation manual, and the use of disqualified or poor oils, antifreeze and water, oil and air

filters.

●

The malfunctions of the portions and parts due to self modification, adjustment and assembly

and disassembly, which are disallowed for self adjustment or assembly and disassembly as

specified in the operation manual.

●

The oil, antifreeze, filter element, hose, belt and fuel injector coupling replaced during normal

use, consumption and maintenance.

●

There is warranty evidences (warranty card and invoice) and the coverage of warranty period

for the product purchased can’t be proved. The product specification and model on the

warranty evidence or invoice are not consistent with the product requested for warranty

service or there is a trace of modification on the warranty evidence or invoice.

●

The failure to maintain the original statue in event of malfunction and the self handing, which

leads to impossible technical authentication of the malfunction cause.

●

The malfunction arising from misoperation.

●

The damages arising from force majeure, such as war and natural disaster.

●

The diesel engine is damaged on the vehicle after traffic accident.

41

WEICHAI

Rule of Warranty Period for Weichai Power Diesel Engine

No.

Product Model

Warranty period

Remarks

I. Complete diesel engine

1

Diesel engine for road vehicles

1 year or 60,000km

2

Diesel engine for engineering vehicles

0.5 year or 30,000km

3

Diesel engine for buses

1 year or 100,000km

4

Gas engine for buses

1 year or 100,000km

II. Diesel engine parts

2 years or 200,000km

(attributed to original

1

Basic parts

Cylinder block, crankshaft, engine base and connecting rod

manufacture defect, such

as sand inclusion)

Cylinder head, flywheel, flywheel housing, connecting rod bolt,

Follow the warranty

piston, piston ring, piston pin, connecting rod bushing, main

period of above complete

Based on the

shaft bushing, camshaft bushing, camshaft, cylinder liner, valve,

diesel engine.

actual sales date

valve spring, valve seat, valve guide tube, valve cover, tappet,

and the sales

tapper rod, rocker arm and rockshaft, various gears and gear

invoice,

shafts, tensioner, gear ring, oil pump, intake and exhaust

warranty card,

manifolds, oil sump, pulley, high pressure fuel pump, fuel

or timer.

Important

injector body, air compressor, various cover plates and pads,

2

parts

water pump, oil radiator, silicone oil clutch, pressure limiting

valve, shock absorber, crankshaft balancer, various metal oil

pipes, water pipes and pipe connectors, steering pump,

thermostat, fuel-water separator, cylinder gasket, ECU, common

Warranty period

rail tube, air cleaner body, diesel filter body, oil filter body,

or mileage

muffler, distribution disc, starter valve, inter-cooler, thermal

(hour),

exchange, air reservoir, thrust plate, strainer, oil dipstick

whichever

subassembly, cooling oil nozzle, SCR tank and urea tank.

comes first.

Front oil seals and other oil seals, turbocharger, intake manifold

6 months or 30,000km for

gasket, exhaust manifold gasket, turbocharger gasket, valve

road vehicles. 3 months or

General

3

cover gasket, rubber hose, fuel injector return pipe, fuel delivery

15,000km for engineering

parts

pump, oil dipstick, fan, water-proof and oil-proof rubber rings,

vehicles. 6 months or

and cup plug.

50,000km for buses.

6 months or 30,000km for

Starter, alternator, instruments, various sensors, electric

road vehicles. 3 months or

Electric

4

regulators, throttle pedal, harness, solenoid valve and flame

15,000km for engineering

units

preheater.

vehicles. 6 months or

50,000km for buses.

5,000km or within

Wearing

Belt, shroud, fuel injector nozzle, plunger coupling, other

mandatory maintenance

5

parts

gaskets, various braided hoses, clamps and timer.

period. 1 month or

10,000km for buses.

Note: 1.

If the engine odometer of the road vehicle is damaged, the warranty period will be calculated based on 325km a day.

2.

If the engine odometer of the engineering vehicle is damaged, the warranty period will be calculated based on 300km a day.

3.

If the engine odometer of the bus is damaged, the warranty period will be calculated based on 400km a day for touring buses

and 200km a day for public buses.

4.

The road vehicles include trucks, truck-mounted cranes, and mixer trucks and the engineering vehicles include dump trucks.

5.

If the vehicle manufacturer has explicit rules, such rules shall be followed.

42

WEICHAI

Weichai International Marketing Service Network

Area

Office

Sales

Service

Local TEL

Mobile

E-mail

Address

in charge

in charge

Russia

An pengfei

0074953152825

0079267519073

weichairussia@yahoo.com.cn

117519, ɝ.Ɇɨɫɤɜɚ ɭɥ.ɤɢɪɨɜɨɝɪɚɞɫɤɚɹ , ɞɨɦ 32,Ⱥɩɚɪɬɨɬɟɥɶ ɗɊɂȾȺɇ ɤɜ.15-ɋ1

Commonwealt

Mongolia

Liu w eijun

00976-99602398

mongoliaweichai@yahoo.com.cn

h of indenpent

Tutubalin

States

Kazakstan

Shan hongwu

0077011725466

kazakstanweichai@yahoo.com.cn

Ɋɟɫɩɭɛɥɢɤɚ Ʉɚɡɚɯɫɬɚɧ , ɝ.Ⱥɥɦɚɬɵ, ɭɥ.Ȼɭɡɭɪɛɚɜɚ 23

Azərbaycan,Baki,Nəsimi,2-ci Mikrorayon,Rəúid Məmmədov,ev 0025,mən

Azerbaijan

Zhang lei

00994-773301769

syriaweichai@yahoo.com.cn

0099

S in gap ore

Zhang jingping

Indonesia

Zhang jingping

Dai liancheng

0065-67794869

0065 9623 4801

dailc@weichai.com.sg

WESTECH BUILDING No 237, PANDAN LOOP,#05-11 SINGAPORE 128424

Philippines

Wang hongshan

Southeast

Vietnam

Xue hua

Asia

Hong kong

Zhang jingping

Liu haitao

0085293364201

hongkongweichail@yahoo.com.cn

235/1,Seri-onnut Village,Onnut Soi 70/1,Sukhumvit 77 Road,Khet

Thailand

Zhuo laixian

Zhang yunjian

0066-27212357

0066-867001639

thailandweichai@yahoo.com.cn

Pravate,Bangkok 10250 Thailand

ROOM NO.14-08, 17 FLOOR, BLOCK (D),

Burma

Liu sen

wang jiaquan

0095-1-541348

0095-9-5008728

lius@weichai.com

PEARL CONDO, BAHAN TOWNSHIP,

Bangladesh

Liu jingrui

zhang yong

liujingr@weichai.com

South Asia

India

Li jian

Pan shankao

0091-20-30262800

0091-7387006182

lijian@weichai.com

No.201,Pentagon-3,Magarpatta City,Hadapsar,Pune-

411013,Maharashtra,India

United Arab

Chen yun

0097142381447

00971509420629

uaeweichai@yahoo.com.cn

F lat N o .7 05,Jscom e T ow er-11 ,A l Q u sais-1,A l Q usa is,D u bai,U A E .

Emirates

M id dle e ast

Iran

Sun lifeng

Zhong lei

00982122344130

00971506753806

iranweichai@yahoo.com.cn

No.1,Floor-7,Block-11,Atisaz,EXP,Chamran,Tehran,Iran

Saudi Arabia

Sui zhen

00966-56-2108200

saudiweichai@gmail.com

Villa No.17, Dana compound, Naseem Dist. Khurais Road Exit 30, Riyadh,

saudiweichai@yahoo.cn

Kindom of Saudi Arabia

Italy

haof@weichai.com

Europe

Hao feng

France

zhanggp@weichai.com

algeriaweichai@yahoo.com.cn

Algeria

Huo chunlei

00213551883843

Cite Krim Belkacem ilot 17 n。 14-Dar El Beida-Alger-Algerie

North Africa

Gao donghai

Egypt

Zhou jingwei

00201125846195

egyptweichai@yahoo.com.cn

ﺔﻳرﻮﻬﻤﺟ ﺮﺼﻣ ﺔﻴﺑﺮﻌﻟا -ةﺮهﺎﻘﻟا -ﺔﻨﻳﺪﻣ ﺮﺼﻧ -40 عرﺎﺷ مﺎﻣﻻا ﻲﺑا ﺔﻔﻴﻨﺣ ﻲﺤﻟا ﻊﺒﺴﻟا

No.601 lakeside apartment, kiambu lane road kizingo mombasa

Kenya

Cao lei

00254-705978578

kenyaweichai@yahoo.com.cn

P.O.Box:99206 Mombasa

East Africa

Ethiopia

Gao jingui

Hu xiaoqun

00251-924909463

ethiopiaweichai@yahoo.com.cn

P.O.BOX 1947 .Debre Zeit, Ethiopia TOMMY INTERNATIONNAL HOTEL

00249

Sundan

Wang zimao

00249 922868539

sudanweichai@126.com

ﻊﻤﺠﻣ ﺮﺼﻧ ﻲﻨﻜﺴﻟا ةرﺎﻤﻌﻟا أ 15 ﻖﺑﺎﻃ

1 ﺔﻓﺮﻏ 02 ﻲﻓ مﻮﻃﺮﺨﻟا ﺔﻤﺻﺎﻌﻟا نادﻮﺴﻟا.

155255168

South Africa

Wan kuishao

0027717282045

nanfeiweichai@163.com

11 Glenrosa, 30 Arterial Road, Bedfordview, Johannesburg, South Africa.

South Africa

Wan kuishao

Angola

Fu yongsheng

00244924771275

angolaweichai01@yahoo.com.cn

West Africa

Nigeria

Wang ge

Wang changcong

00234-8155777771

nigeriaweichai@yahoo.com.cn

No22,citrus close, Alfred garden estate Oregun Ikeja, Lagos State.

Venezuela

Xia jianning

00233-541164989

wanglu@weichai.com

South America

Cuba

Wang lu

Huang jinggui

0053-07-2033597

GUBAHUANGJG@126.com

Calle21#8214e/82y84PlayaHabanaCuba.

Brazil

Song zhiping

005511976427085

brazilweichai@yahoo.com.cn

rua pires da mota 647,aclimacao,sao paulo,brazil

North America

America

Liu haifeng

+1(847)718-0602

liuhf@weichai.com

3100 Golf Rd,Rolling Meadows, IL,US

43

Engine Mandatory Maintenance Card

License plate number

Manufacturer

User name

Engine number

Mandatory maintenance date

Detailed address

Mandatory maintenance mileage

Purchaser

Purchase date

Audited by:

User signature:

Weichai Power special engine oil

label:

Valid certificate:

Seal of service station:

Customer tel.:

Tips: This mandatory card is in triple sheets and must be signed by customer for approval. All items shall be filled

and the card with missing item will be considered void.

Supervision Tel. of Weichai Power: 400-6183066

800-8603066

At completion of mandatory maintenance, the service station shall summarize the offices within responsible region

along with the Customer Satisfaction Survey attached in this manual.

Engine Mandatory Maintenance Card

License plate number

Manufacturer

User name

Engine number

Mandatory maintenance date

Detailed address

Mandatory maintenance mileage

Purchaser

Purchase date

Audited by:

User signature:

Weichai Power special oil label:

Valid certificate:

Seal of service station:

Customer tel.:

Tips: This mandatory card is in triple sheets and must be signed by customer for approval. All items shall be filled

and the card with missing item will be considered void.

Supervision Tel. of Weichai Power: 400-6183066

800-8603066

At completion of mandatory maintenance, the service station shall summarize the offices within responsible region

along with the Customer Satisfaction Survey attached in this manual.

Engine Mandatory Maintenance Card

License plate number

Manufacturer

User name

Engine number

Detailed address

Mandatory maintenance date

Mandatory maintenance mileage

Purchaser

Purchase date

Audited by:

User signature:

Weichai Power special oil label:

Valid certificate:

Seal of service station:

Customer tel.:

Tips: This mandatory card is in triple sheets and must be signed by customer for approval. All items shall be filled

and the card with missing item will be considered void.

Supervision Tel. of Weichai Power: 400-6183066

800-8603066